潜水泵综合指南(中英文)

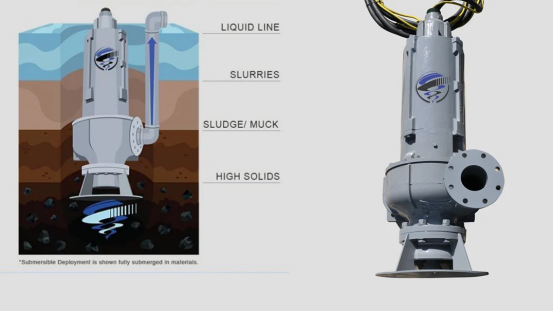

想要改变公司处理过度洪水和泥浆积聚的方式,不妨考虑一下工业潜水泵,它旨在改变各行各业和住宅环境中的流体处理方式。这些泵完全潜入水中运行,无需泵房,并降低了安装成本。

潜水泵广泛应用于洪水淹没区域的排水,污水处理,井水抽取等。它们能够处理多种类型的液体,是工业和住宅环境中不可或缺的设备。本文将深入探讨潜水泵的世界,探索其在流体处理领域的潜力。

Looking to transform the way your company handles excessive flooding and slurry buildup? Consider industrial submersible pumps, designed to transform fluid handling in various industries and residential settings. These pumps operate fully submerged, eliminating the need for pump houses and reducing installation costs.

Submersible pumps find applications in draining flooded zones, handling sewage, extracting well water, and more. Their ability to manage diverse liquid types makes them indispensable in industrial and residential contexts. In this article, we dive into the world of submersible pumps to unlock their potential for your fluid handling needs.

什么是潜水泵?

What is a Submersible Pump?

潜水泵是一种专用的流体处理设备,设计为完全浸没在被输送液体中运行。这种设计无需非潜水泵通常需要的泵房或吸程,从而提高了运行效率并降低了安装成本。

潜水泵的主要部件包括电动机,叶轮和泵壳。电动机采用全密封设计,与泵体紧密结合,确保泵体不渗透,并防止液体渗入,避免造成电气故障。电动机驱动叶轮——一种旨在提升流体动能的转子。叶轮的结构可能因应用场合和流体特性而异(例如,开放式、半开放式或封闭式)。

潜水泵的应用场景多种多样,包括工业污水泵应用、洪水区排水、污水处理、井水抽取以及油井作业。这类泵在高扬程或高压场合尤其适用,尤其适用于从地面、深层或很深处抽水。

潜水泵操作灵活,能够处理各种液体类型——从纯净水到浓稠泥浆——这使得其在工业环境和住宅环境中都极具价值。潜水泥浆泵专为处理高固体含量的磨蚀性液体而设计,增强了其在严苛环境中的实用性。这些泵固有的潜水运行特性还可以减少噪音污染并节省空间,使其更适合在人口稠密或对噪音敏感的地区使用。

A submersible water pump is a specialized fluid handling device engineered to operate while fully submerged in the liquid it is tasked with moving. This design eliminates the need for a pump house or suction lift, commonly necessary in non-submersible setups, thereby enhancing operational efficiency and diminishing installation expenses.

The primary components of a submersible water pump include an electric motor, an impeller, and a pump casing. The motor is hermetically sealed and intimately integrated with the pump structure, ensuring it remains impermeable and shielded against fluid ingress, which can result in electrical failure. This motor actuates the impeller—a rotor devised to escalate the kinetic energy of the fluid. The impeller’s configuration may vary (e.g., open, semi-open, or closed) depending on the application specifics and the fluid characteristics.

Submersible pumps are deployed in various scenarios, including industrial sump pump applications, draining flooded zones, handling sewage, extracting well water, and operating in oil wells. These pumps are particularly advantageous in scenarios demanding high head or pressure and involving pumping surface, deep, or water from significant depths.

Their operational adeptness, combined with the capacity to manage diverse liquid types—from pristine water to dense slurry—makes submersible pumps exceedingly valuable in both industrial contexts and residential setups. Submersible slurry pumps are tailored explicitly for handling abrasive liquids with high solid content, enhancing their utility in rigorous environments. The inherent submerged operation of these pumps also reduces noise pollution and conserves space, augmenting their suitability in densely populated or acoustically sensitive areas.

了解潜水泵:

Understanding Submersible Pumps:

• 潜水泵的设计:

Design of a Submersible Pump:

潜水渣浆泵经过精心设计,可处理液体混合物中的磨蚀性物料,是采矿、疏浚和重工业领域的必备设备。潜水泵的主要设计部件包括坚固的电动机、高效的叶轮和耐用的泵壳,所有这些部件都经过精心设计,能够承受渣浆输送的严苛要求。

潜水泵的电机被密封在一个防水隔间内,以防止液体和固体进入,这是保持潜水渣浆泵电气完整性和运行可靠性的关键因素。该电机直接与叶轮耦合,优化了能量传输并减少了机械损耗,从而提高了系统的整体效率。

叶轮由高铬合金等耐磨材料制成,是加速浆体流动的动力部件。它利用离心力原理运行,叶轮旋转迫使浆体从泵中心向外径向移动,从而提高浆体的压力,使其通过排放管上升。

潜水泵壳体专为处理浆体中磨蚀性湍流而设计。其形状旨在最大限度地提高流动动力并最大限度地减少磨损,通常配备由橡胶或特殊合金等耐用材料制成的可更换衬套,以延长泵的使用寿命。

总体而言,潜水渣浆泵的设计注重坚固性、运行效率以及处理高密度、高磨蚀性混合物的能力。这使得它在工业污水泵应用中至关重要,确保其在严苛环境中也能可靠运行。

A submersible slurry pump is meticulously engineered to handle abrasive materials within liquid mixtures, making it essential in mining, dredging, and heavy industry sectors. The principal design components of a submersible pump include a robust electric motor, a high-efficiency impeller, and a durable pump casing, all crafted to endure the strenuous demands of slurry transportation.

The electric motor in a submersible pump is hermetically sealed within a watertight compartment to safeguard against the ingress of liquids and solids, a critical factor in maintaining the submersible slurry pump’s electrical integrity and operational reliability. This motor is directly coupled to the impeller, which optimizes energy transmission and reduces mechanical losses, enhancing the system’s overall efficiency.

Constructed from abrasion-resistant materials such as high-chrome alloys, the impeller is the dynamic component that accelerates the slurry. It operates on centrifugal force principles, whereby rotation of the impeller forces the slurry radially outward from the pump’s center to its periphery, thereby elevating the slurry’s pressure and enabling its ascent through the discharge pipe.

The submersible pump casing is specifically designed to handle the abrasive, turbulent flow of the slurry. It is shaped to maximize flow dynamics and minimize wear, often equipped with replaceable liners made from durable materials like rubber or specialized alloys to extend the pump’s lifespan.

Overall, the design of the submersible slurry pump focuses on robustness, operational efficiency, and the capacity to manage dense, abrasive mixtures. This makes it vital in industrial sump pump applications, ensuring reliable performance in challenging environments.

• 潜水泵内部工作原理讲解

Submersible Pump Inner Workings Explained

电机与叶轮集成:工业污水泵采用集成式电机和叶轮,并集成在一个紧凑的密封装置中。这种集成设计使潜水泵即使在完全浸没于工业污水池环境中也能高效运行,因为在这种环境中,持续排水至关重要。

直接耦合:潜水渣浆泵的电机与叶轮直接耦合。这种直接连接方式能够实现从电机到叶轮的卓越能量传输,减少皮带或链条传动系统中常见的能量损失,并提高恶劣工业环境下的运行效率。

离心力机制:工业污水泵启动时,电机驱动叶轮高速旋转。叶轮叶片产生离心力,将水从潜水渣浆泵中心排出到外围,从而优化流体动力学,确保污水泵充分排水。

流体加速和增压:潜水泵壳体的设计以及工业污水泵中叶轮的旋转使水加速,从而提升其动能和压力。这一过程对于通过排水管垂直泵送水至关重要,可以克服深污水池应用中的重力。

预防气蚀:工业污水泵完全浸没在水中运行,可最大程度地降低气蚀风险。气蚀是潜水渣浆泵与水面之间存在较大高差时普遍存在的一个问题。气蚀会导致效率低下和设备损坏;因此,潜水运行有利于预防这些问题。

适用于各种环境:工业污水泵旨在应对各种具有挑战性的应用,从工业污水池的大量排水到工厂的污水和径流管理。潜水渣浆泵能够在水下运行,确保高效可靠,这对于维持工业设施的连续运行至关重要。

Motor and Impeller Integration: The industrial sump pump features an integrated electric motor and impeller within a compact, hermetically sealed unit. This integration allows the submersible pump to function efficiently while fully submerged in industrial sump environments, where continuous water removal is critical.

Direct Coupling: The electric motor is directly coupled to the impeller in the submersible slurry pump. This direct connection provides superior energy transfer from the motor to the impeller, reducing energy losses commonly seen in belt or chain-driven systems and enhancing operational efficiency in harsh industrial settings.

Centrifugal Force Mechanism: When activated, the industrial sump pump’s motor drives the impeller at high speeds. The impeller blades exert centrifugal force to expel water from the center of the submersible slurry pump to its periphery, optimizing fluid dynamics for adequate sump drainage.

Fluid Acceleration and Pressure Increase: The design of the submersible pump casing and the rotation of the impeller in the industrial sump pump accelerate the water, boosting its kinetic energy and pressure. This process is essential for pumping water vertically through the discharge pipe, overcoming the gravitational pull in deep sump applications.

Prevention of Cavitation: Operating fully submerged, the industrial sump pump minimizes the risk of cavitation, a problem prevalent in pumps with significant elevation differences between the submersible slurry pump and the water surface. Cavitation can lead to inefficiency and damage; thus, submersion is beneficial in preventing these issues.

Applications in Diverse Environments: Industrial sump pumps are designed to handle various challenging applications, from draining large volumes of water in industrial sumps to managing effluents and runoff in factories. The ability of the submersible slurry pump to operate while submerged ensures high efficiency and reliability, which is critical for maintaining operational continuity in industrial facilities.

潜水泵的类型:

Types of Submersible Pumps:

潜水泵的设计和应用多种多样,可根据特定的操作要求和环境进行定制。以下是不同类型的潜水泵的细分:

• 潜水泵:

这些泵旨在高效输送不含大颗粒或污染物的水。它们用途广泛,可用于各种场合,例如排水系统、水池和公用设施。

• 潜水渣浆泵:

这款潜水泵专为在磨蚀性泥浆混合物中潜水运行而设计。它在采矿、疏浚和建筑行业中必不可少,用于处理沙子、砾石和其他碎屑等物料。其设计包括涡流叶轮等功能,可有效处理较大的固体颗粒。

• 钻孔泵:

这些潜水泵专为深层地下应用而设计,尤其适用于狭窄深井(称为钻孔)。它们配备强大的电机和液压系统,可从深层水源抽水,这对于农业和工业生产至关重要。

• 充油泵:

这些潜水泵在农业中常用于从井中提水,其电机由周围的油冷却,使其能够在较冷的环境中运行而不会结冰。

• 不锈钢潜水泵:

不锈钢结构以其耐用性和耐腐蚀性而闻名,进一步提升了其使用寿命和性能。它们适用于暴露于腐蚀性液体的环境。

• 潜水泵:

这些紧凑便携的泵在建筑工地和紧急情况下非常有用。它们可以排出被水淹没的区域、清空水池并输送液体。

• 增压泵:

这些潜水泵可在水量不足的系统中增加水流量和水压。它们可用于住宅、商业和工业环境,以确保充足的供水。

• 高温潜水泵:

它们设计用于处理高温流体,非常适合需要耐热操作的特定工业应用。

• 潜水灌溉泵:

这些潜水泵主要用于农业。它们能高效地为农作物供水,并能从深层水源抽取大量水。

每种类型的潜水泵都设计有特定的功能,以满足各种环境和材料的需求,确保在广泛的应用中高效可靠地运行。

Submersible pumps are diverse in their designs and applications, tailored to specific operational requirements and environments. Here’s a breakdown of the different types of submersible pumps:

• Submersible Water Pumps:

These pumps are designed to move water efficiently without large particles or contaminants. They are versatile and used in various settings, such as drainage systems, pools, and utilities.

• Submersible Slurry Pumps:

This submersible pump is built to operate while submerged in abrasive slurry mixtures. It is essential in mining, dredging, and construction, handling materials like sand, gravel, and other debris. Its design includes features like vortex impellers to manage larger solids effectively.

• Borehole Pumps:

These submersible pumps are engineered for deep underground applications, particularly in narrow, deep wells known as boreholes. They are equipped with powerful motors and hydraulic systems to draw water from deep sources, which is crucial in agriculture and industrial processes.

• Oil-Filled Pumps:

Common in agriculture for lifting water from wells, these submersible pumps have motors cooled by surrounding oil, allowing them to operate in colder environments without freezing.

• Stainless Steel Submersible Pumps:

Known for their durability and corrosion resistance, stainless steel construction enhances their longevity and performance. They are suitable for environments exposed to corrosive liquids.

• Submersible Utility Pumps:

These compact and portable pumps are invaluable in construction sites and emergencies. They can drain flooded areas, empty pools, and transfer liquids.

• Booster Pumps:

These submersible pumps increase water flow and pressure in systems where it is inadequate. They can be employed in residential, commercial, and industrial settings to ensure adequate water supply.

• High-Temperature Submersible Pumps:

These are designed to handle fluids at elevated temperatures and are well-suited for specific industrial applications requiring heat-resistant operations.

• Submersible Irrigation Pumps:

These submersible pumps are predominantly used in agriculture. They efficiently deliver water to crops and can lift significant volumes from deep sources.

Each type of submersible pump is designed with specific features to meet the demands of various environments and materials, ensuring efficient and reliable operation across a wide range of applications.

潜水泵的应用:

Applications of Submersible Pumps:

潜水泵,尤其是潜水渣浆泵和工业污水泵,是各行各业众多关键应用不可或缺的一部分。潜水泵的主要应用如下:

废水管理:

工业污水泵广泛应用于污水处理设施。这些泵擅长处理固体和液体,非常适合输送废水,包括碎屑、有机废物和其他颗粒物。

采矿和疏浚:

潜水渣浆泵是采矿业输送磨蚀性高密度渣浆的必备设备。这类泵可用于尾矿管理、池塘疏浚和沉积物输送,在恶劣的采矿和疏浚环境中也能提供强劲的性能。

石油和天然气:

潜水渣浆泵在石油和天然气行业的海上钻井作业中发挥着至关重要的作用。它们能够高效地管理钻井泥浆等研磨性物质,并通过清除钻井现场的副产品来确保开采过程的不间断。

建筑和基础设施:

潜水渣浆泵对于建筑项目至关重要,尤其是在大型挖掘和开发工程的脱水方面。它们可以有效地管理地下水和地表水,保持施工现场干燥。

环境修复:

潜水渣浆泵用于环境清理项目,以清除污水、污泥和其他污染物。其坚固的设计使其能够处理危险物质,有助于生态系统恢复和污染控制。

农业和灌溉:

工业污水泵通过促进高效灌溉来支持农业。它们从深层水源抽水,提供所需的水量和压力,从而在广阔的农田中均匀分配水量。

Submersible pumps, particularly the submersible slurry and industrial sump pumps, are integral to numerous critical applications across various sectors. Here are the primary applications of the submersible pumps:

Wastewater Management:

Industrial sump pumps are extensively employed in wastewater treatment facilities. These pumps are adept at handling solids and liquids, making them perfect for moving wastewater, including debris, organic waste, and other particulates.

Mining and Dredging:

The submersible slurry pump is essential for transporting abrasive and dense slurries in the mining industry. These pumps are used for tailings management, pond dredging, and sediment transport and provide robust performance in harsh mining and dredging environments.

Oil and Gas:

Submersible slurry pumps play a critical role in offshore drilling operations in the oil and gas sector. They efficiently manage abrasive materials such as drilling mud and ensure uninterrupted extraction processes by removing by-products from the drilling site.

Construction and Infrastructure:

Submersible slurry pumps are crucial for construction projects, particularly for dewatering large-scale excavations and developments. They effectively manage groundwater and surface water to keep construction sites dry.

Environmental Remediation:

Submersible slurry pumps are used in environmental cleanup projects to remove contaminated water, sludge, and other pollutants. Their robust design enables them to handle hazardous materials, aiding ecosystem restoration and pollution control.

Agriculture and Irrigation:

Industrial sump pumps support agriculture by facilitating efficient irrigation. They draw water from deep sources to deliver the necessary volume and pressure for uniform water distribution across expansive agricultural fields.

潜水泵的优点:

Benefits of Submersible Pumps:

潜水泵(包括潜水水泵、泥浆泵和工业污水泵)与传统泵相比具有诸多优势,尤其是在处理复杂且高要求的泵送任务时。以下是这些泵的一些关键优势:

高效运行:

潜水泵(主要是潜水水泵)的工作原理是推动液体而不是拉动液体。这种方法效率很高,因为它利用了泵浸没在液体中的水头,并利用周围的压力来辅助泵送。与必须将液体吸入系统的传统泵相比,这种效率降低了所需的能量。

增强冷却和保护:

潜水泵的潜水运行确保周围流体持续冷却电机。这可以延长电机的使用寿命,并防止非潜水泵常见的过热问题。

降低气蚀风险:

潜水泵不太可能发生气蚀,气蚀会严重损坏泵组件。潜水泵在水下工作时,能够保持必要的压力水平,防止形成导致气蚀的气泡。

应用的多功能性:

潜水渣浆泵和工业污水泵可以处理各种介质类型,包括清水、污水、油和磨蚀性渣浆。这种多功能性使其适用于从排水和污水系统到复杂工业流程的多种应用。

维护和安装成本低:

潜水泵结构紧凑,无需像泵房那样进行大规模安装,因此更易于维护,安装和维护成本也更低。其流线型设计最大限度地减少了运行所需的物理空间,这在拥挤或空间有限的环境中具有显著优势。

提高安全性:

潜水泵的所有组件均牢固地封装在一个密封单元内,从而最大程度地降低了泄漏或接触危险物质的风险。这一特性增强了安全性,尤其是在涉及危险或受污染流体的应用中。

Submersible pumps, including submersible water, slurry, and industrial sump pumps, offer several advantages over traditional pumps, especially when handling complex and demanding pumping tasks. Here are some of the critical benefits of these pumps:

Efficient Operation:

Submersible pumps, mainly submersible water pumps, operate by pushing fluid rather than pulling it. This method is highly efficient as it leverages the head of liquid where the pump is submerged, utilizing the surrounding pressure to assist in pumping. This efficiency reduces the energy required compared to traditional pumps that must draw liquid into their systems.

Enhanced Cooling and Protection:

Submersible pumps’ submerged operation ensures the surrounding fluid consistently cools the motor. This extends the motor’s lifespan and prevents overheating, a common issue in non-submerged pumps.

Reduced Cavitation Risk:

Submersible pumps are less likely to experience cavitation, which can significantly damage pump components. Being submerged, these pumps maintain the necessary pressure levels to prevent the formation of vapor bubbles that cause cavitation.

Versatility in Applications:

Submersible slurry and industrial sump pumps can handle various media types, including clean water, dirty water, oil, and abrasive slurries. This versatility makes them suitable for multiple applications, from drainage and sewage systems to complex industrial processes.

Low Maintenance and Installation Costs:

Submersible pumps are compact and do not require extensive installation setups like pump houses, making them more accessible and less costly to install and maintain. Their streamlined design minimizes the physical space needed for operation, a significant advantage in crowded or limited-space environments.

Improved Safety:

Submersible pumps minimize the risk of leaks or exposure to hazardous materials, as all components are securely contained within a single sealed unit. This feature enhances safety, particularly in applications involving hazardous or contaminated fluids.

潜水泵的维护:

Maintenance of Submersible Pumps:

维护潜水泵(包括潜水水泵和潜水渣浆泵)对于确保其使用寿命和最佳性能至关重要。以下详细介绍了如何维护这些泵,以实现更长的使用寿命和更高的成本效益:

例行检查:

定期检查对于及早发现潜在问题至关重要。检查潜水泵和渣浆泵是否有磨损或损坏的迹象,例如裂纹、腐蚀或运行过程中的异常噪音。检查电缆和连接处是否有任何老化或泄漏的迹象。

清扫:

潜水渣浆泵通常在颗粒物含量高的环境中运行,应定期清洁,以防止堵塞和碎屑堆积。清洁工作包括将泵从其运行环境中移除,必要时将其拆卸,并使用合适的清洁剂清洁所有可接触的部件。

叶轮调整和更换:

叶轮是关键部件,如果磨损或错位,会影响泵的效率。定期检查叶轮是否有任何损坏或过度磨损的迹象。调整或更换叶轮,以保持潜水泵或潜水渣浆泵的最佳性能。

密封件更换:

潜水泵的密封件可保护其电气元件免受水的侵蚀。为防止泄漏和潜在的电机故障,应定期检查这些密封件,并在出现磨损或损坏迹象时进行更换。

润滑:

一些潜水泵,尤其是带有轴承和其他运动部件的潜水泵,需要定期润滑以确保平稳运行。请使用推荐的润滑剂,并遵循制造商关于润滑频率和润滑量的指导。

电气测试:

定期进行电气测试,确保泵电机和控制系统的完整性。这包括检查绝缘电阻和电压测试,以便在潜在的电气故障导致更严重的问题之前发现它们。

性能监控:

定期监测潜水泵和潜水渣浆泵的性能,确保其在设计参数范围内运行。留意流量、压力或能耗的任何变化,这些变化可能预示着潜在的问题。

文件和记录保存:

保留所有维护活动的详细记录,包括检查、零件更换和维修。这些记录有助于追踪泵的历史记录并预测未来的维护需求,从而增强预防性维护策略。

通过遵循这些维护程序,操作员可以显著延长潜水泵和渣浆泵的使用寿命,确保其高效可靠地运行。定期彻底的维护可以防止意外停机,并通过最大限度地减少昂贵的维修或更换需求来降低总体拥有成本。

Maintaining submersible pumps, including submersible water pumps and submersible slurry pumps, is crucial to ensure their longevity and optimal performance. Here’s a detailed explanation of how to maintain these pumps for extended and cost-efficient operations:

Routine Inspection:

Regular inspections are essential for early detection of potential issues. Inspect the submersible water pump and slurry pump for signs of wear or damage, such as cracks, corrosion, or abnormal noises during operation. Check the electrical cables and connections for any signs of deterioration or leakage.

Cleaning:

Submersible slurry pumps, which often operate in environments with high particulate matter, should be cleaned regularly to prevent clogging and debris buildup. This involves removing the pump from its operating environment, disassembling it if necessary, and cleaning all accessible parts with appropriate cleaning agents.

Impeller Adjustment and Replacement:

The impeller is a critical component that can affect the pump’s efficiency if worn or misaligned. Check the impeller periodically for any signs of damage or excessive wear. Adjust or replace the impeller to maintain the optimal performance of the submersible water pump or submersible slurry pump.

Seal Replacement:

The seals of a submersible pump protect its electrical components from water ingress. To prevent leaks and potential motor failure, these seals should be inspected regularly and replaced if they show signs of wear or damage.

Lubrication:

Some submersible pumps, especially those with bearings and other moving parts, require regular lubrication to ensure smooth operation. Use the recommended lubricant and follow the manufacturer’s guidelines regarding the frequency and quantity of lubrication.

Electrical Testing:

Perform regular electrical tests to ensure the integrity of the pump’s motor and control system. This includes checking the insulation resistance and voltage testing to detect potential electrical failures before they lead to more significant issues.

Performance Monitoring:

Monitor the performance of the submersible water pump and submersible slurry pump regularly to ensure they operate within their designed parameters. Look for any changes in flow rate, pressure, or energy consumption that could indicate underlying problems.

Documentation and Record Keeping:

Keep detailed records of all maintenance activities, including inspections, part replacements, and repairs. This documentation will help track the pump’s history and predict future maintenance needs, enhancing the preventative maintenance strategy.

By following these maintenance procedures, operators can significantly extend the lifespan of submersible water and slurry pumps, ensuring they operate efficiently and reliably. Regular and thorough maintenance prevents unexpected downtime and reduces the overall cost of ownership by minimizing the need for costly repairs or replacements.

购买潜水泵时常见的错误及避免技巧:

Common Mistakes While Buying a Submersible Pump and Tips to Avoid Them:

购买潜水泵时需要仔细考虑,避免一些可能导致效率低下和成本增加的常见错误。以下是购买潜水泵时的一些常见错误以及如何避免这些错误的提示:

尺寸和容量不正确:

选择容量不适合应用的潜水泵会导致效率低下,例如能耗过高或流量不足。

解决方案:详细分析应用的流量和扬程要求。咨询相关技术人员,他们可以根据性能曲线和系统要求提供指导。

忽略液体的特性:

如果不考虑液体的特性,例如温度、化学成分和固体含量,可能会导致过早磨损或泵故障。

解决方案:选择适合液体特性的泵材质和类型。例如,在酸性条件下使用耐腐蚀材料,在高固体含量的液体中则选择工业污水泵。

安装环境概览:

在不合适的环境中安装泵会影响其性能和使用寿命。

解决方案:评估安装地点的深度、空间和可达性。确保潜水泵与潜水深度和温度等环境条件兼容。

忽略泵效率:

购买泵时考虑其效率可能会导致更高的运营成本。

解决方案:寻找高效低能耗的潜水泵。查看效率图表,选择在所需工况下运行效率最高的泵。

为了成本而牺牲质量:

选择更便宜、质量更低的泵可能会导致频繁故障和更高的维护成本。

解决方案:投资信誉良好的制造商生产的高质量潜水泵。虽然初始成本可能较高,但长期节省的维护和更换成本值得这项投资。

未能考虑未来的需求:

购买满足当前需求而不考虑未来需求的泵会限制可扩展性和适应性。

解决方案:预测运行条件的潜在变化,并选择具有一定容量的潜水泵来应对增加的需求或不同的运行条件

Purchasing submersible pumps involves careful consideration to avoid common mistakes that can lead to inefficiencies and increased costs. Here are some common mistakes while buying a submersible pump and tips on how to avoid them:

Incorrect Sizing and Capacity:

Choosing a submersible pump with inappropriate capacity for the application can lead to inefficiencies such as excessive energy consumption or insufficient flow rate.

Solution: Conduct a detailed analysis of your application’s flow rate and head requirements. Consult with engineers or sales representatives who can provide guidance based on performance curves and system requirements.

Neglecting the Liquid’s Characteristics:

Failing to consider the liquid’s characteristics, such as temperature, chemical composition, and solid content, can cause premature wear and tear or pump failure.

Solution: Select a pump material and type suitable for the liquid’s properties. For example, use corrosion-resistant materials for acidic conditions and choose an industrial sump pump for liquids with high solid content.

Overlooking the Installation Environment:

Installing the pump in an unsuitable environment can affect its performance and longevity.

Solution: Evaluate the installation site for depth, space, and accessibility. Ensure that the submersible pump is compatible with the environmental conditions, such as submersion depth and temperature.

Ignoring Pump Efficiency:

Purchasing a pump with consideration of its efficiency can lead to higher operational costs.

Solution: Look for submersible pumps with high-efficiency ratings and low energy consumption. Review efficiency charts and select a pump that operates most efficiently at your required operating point.

Skimping on Quality for Cost:

Opting for cheaper, lower-quality pumps can result in frequent breakdowns and higher maintenance costs.

Solution: Invest in high-quality submersible pumps from reputable manufacturers. While the initial cost may be higher, the long-term savings in maintenance and replacement costs justify the investment.

Failing to Consider Future Needs:

Purchasing a pump that meets immediate needs without considering future requirements can limit scalability and adaptability.

Solution: Anticipate potential changes in operational conditions and choose a submersible pump with some capacity to handle increased demands or different operating conditions

结论:

Conclusion:

潜水泵是流体处理领域效率和可靠性的产品。其用途广泛,设计耐用且维护成本低,使其成为全球各行各业不可或缺的资产。无论是排干积水区域、管理污水还是处理磨蚀性泥浆,潜水泵都能提供优质的性能。

Submersible pumps are the pinnacle of efficiency and reliability in fluid handling. Their versatile applications, durable designs, and minimal maintenance requirements make them indispensable assets across industries worldwide. Submersible pumps offer unparalleled performance, whether draining flooded areas, managing sewage, or handling abrasive slurries.

声明:

-文章转载自EDDYPUMP,由爱泽工业翻译,如有侵权,请联系删除!

-如有偏颇,欢迎指正!

下一篇:爆破片的应用(中英文)

沪公网安备31011002006738号

沪公网安备31011002006738号