螺杆泵详解:核心部件,工作原理与应用(中英文)

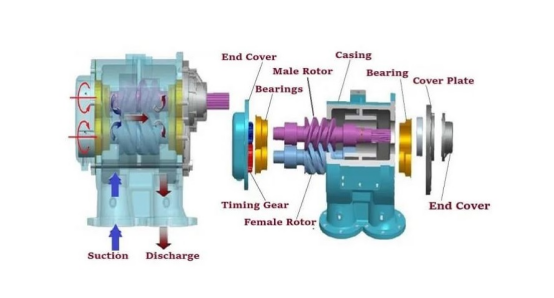

螺杆泵的部件——螺杆泵是一种常见的容积式泵。它的另一个名称是水螺杆泵。螺杆泵是一种利用一个或多个螺杆沿螺杆轴线输送流体或水的装置。为了加压流体并将其输送到系统内部,这些螺杆相互啮合。这些螺杆相互缠绕,并在气缸的空腔内往复运动。螺杆泵由许多部件组成,包括壳体、螺杆(根据螺杆泵的类型,螺杆数量可能从一到五个不等)、轴承、密封件、电机适配器和驱动轴。螺杆泵的设计简洁明了。

Parts of Screw Pump – A screw pump is a well-known positive displacement pump type. A water screw pump is another name for it. A screw pump is a device that employs one or more screws to transfer fluids or water along the screw’s axis. To pressurize the fluid and transport it inside the system, these screws interlock. These screws are intertwined and reciprocate within the cylinder’s hollow. A screw pump is made up of many components, including a casing, a screw (which may range from one to five screws depending on the kind of screw pump), bearings, a seal, a motor adaptor, and a driving shaft. Screw pumps have a straightforward design.

什么是螺杆泵?

What is a Screw Pump?

顾名思义,螺杆泵的形状类似于螺纹,通过旋转螺纹,流体从泵的吸入侧流向排出侧。由于泵内部间隙相对较小,减少了流体从高压侧滑向低压侧的量,因此泵的容积效率很高,尤其是在输送粘稠流体时。与任何容积泵一样,该泵不产生压力;它仅输送流体;然而,由于摩擦损失,实际系统会产生背压。

水或其他流体通过进气阀进入泵体,并沿着互锁螺钉线性流向泵的出口侧。当流体流过泵体时,螺钉和腔室之间的微小间隙会提高流体压力。

As the name suggests, the screw pump’s shape is similar to a screw thread, and the fluid passes down the screw thread from the suction side to the discharge side of the pump by turning it. The volumetric efficiency of the pump is great, especially with viscous fluids, due to relatively close clearances inside the pump, which lowers the amount of fluid slippage from the high pressure to the low-pressure side. The pump, like any positive displacement pump, does not create pressure; it merely transfers fluid; yet, owing to friction loss, the real system produces backpressure.

Water or other fluids enter the pump through the intake valve and flow linearly along with the interlocking screws toward the outlet side of the pump. When fluid runs through the pump, the tiny space between the screw and the chamber raises the fluid pressure.

旋转螺杆泵广泛应用于各行各业,包括发电、化学加工、航运、炼油厂、码头、管道以及油气开采。这些泵可用于顶管油、高压燃油喷射、燃油输送、齿轮和轴承润滑,以及用于发电区水力发电设施管理的水力发电。

水螺杆泵,也称为螺杆泵,是一种旋转部件很少且维护成本极低的机器。借助这类泵,您可以高效地泵送各种粘度、压力和体积范围内的固定体积物料。

螺杆泵的结构简单可靠,制造起来也非常简单。它总共有三根螺杆,其中两根为从动螺杆,一根为驱动螺杆。这些螺杆之间留有足够的空间,用于泵送水或其他流体。流体由电动机输送至螺杆。

这种泵的壳体具有吸入侧和排出侧。吸入阀位于泵的底部,排出阀位于顶部。排出侧还设有一个止回阀,用于阻止流体回流。泵的设计体现了所有这些特点。

Rotary screw pumps are used in a wide range of industries, including power generation, chemical processing, shipping, refineries, terminals, pipelines, and oil and gas extraction. These pumps are used for jacking oil, high-pressure fuel injection, fuel delivery, gear and bearing lubrication, and water power for applications in the management of hydroelectric facilities in the power-producing zone.

The water screw, also known as a screw pump, is a machine with few spinning components that requires extremely little maintenance. You can efficiently pump fixed volume items in a variety of viscosity, pressure, and volume ranges with the aid of these pumps.

The construction of a screw pump is simple and dependable. It is really simple to create. There are three screw spindles in all, two of which are driven screws and one of which is a driver. There is sufficient room between these screws, which are in charge of pumping water or other fluid. The fluid is supplied to the screws by an electric motor.

A housing having suction and discharge sides is used in this type of pump. The suction valve is found at the bottom of the pump, while the discharge valve is found at the top. It also contains a check valve on the discharge side that stops the fluid from flowing backward. The pump design reflects all of this.

螺杆泵的 7 个主要部件

7 Main Parts of Screw Pump

螺杆泵的 7 个零件分别是:

• 进水口和出水口

• 主动螺杆

• 正时齿轮

• 轴承

• 从动螺杆

• 泄压阀

• 驱动轴

7 parts of screw pump are:

• Inlet & Outlet Ports

• Driver Screw

• Timing Gear

• Bearings

• Driven Screw

• Pressure Relief Valve

• Driving Shaft

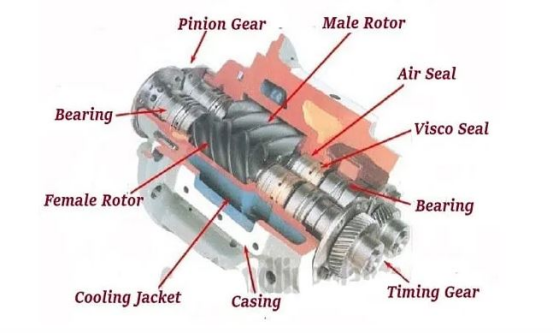

主动螺杆

它是螺杆泵的旋转部件。主动螺杆连接到电机的驱动轴。它有助于保持流体泵送的恒定体积流量。正时齿轮连接到一端,驱动轴连接到另一端。

从动螺杆由主动螺杆驱动旋转,驱动螺杆由电机驱动轴驱动。主动螺杆与从动螺杆配合良好。该螺杆采用高强度钢制造。主动螺杆的主要作用是通过作为中间部件的正时齿轮驱动从动螺杆旋转。

从动螺杆

从动螺杆也采用高强度钢制成。由于正时齿轮传递的运动,从动螺杆绕其轴线旋转。其旋转方向与驱动齿轮相反。该螺杆的间隙面积恒定。这有助于在有限的空间内捕获水分。

随着主动螺杆和从动螺杆的同步移动,水量减少并流向出水口。由于这种运动,流体压力上升。然后,流体通过出水口排出。

正时齿轮

正时齿轮驱动从动螺杆,使阴转子组件和阳转子组件之间不发生金属接触。它在主动螺杆和从动螺杆之间建立了连接。主动螺杆带动正时齿轮旋转,正时齿轮再将旋转传递给从动螺杆。正时齿轮以这种方式驱动螺杆。即使泵短时间关闭,也能确保不会发生此类接触。

进水口和出水口

螺杆泵的进水口和出水口截然不同。水通过进水口吸入泵内,并通出水口排出。泵最终停止运行时,进水口和出水口的设计可确保泵内有足够的液体介质。这有助于泵初始液体介质的输送。因此,即使吸入管是空的或干燥的,也不会快速干涸。

泄压阀

螺杆泵是一种容积式泵,即使出口关闭,压力也会累积。压力累积可能导致严重问题,包括泵内部零件损坏以及泵操作员受伤。因此,每个容积式泵都配有安全阀,以保护泵、操作员和任何相关设备。多余的压力通过此阀返回到吸入口。循环出口流体是另一种常见的降低额外压力的方法。

轴承

在泵运行过程中,垂直安装的螺杆泵的上轴承承受着很大的载荷以及轴向和径向应力。因此,下轴承的载荷很小。

底部轴承的主要功能是保持泵部件对齐。另一方面,螺旋泵、滚柱轴承和滑动轴承平行安装时,负载相对较低。这是因为产生的径向力和轴向力相互抵消。

驱动轴

驱动轴将泵组件与驱动电机连接起来。这种连接是通过使用合适的柔性联轴器来实现的。

驱动轴是许多类型泵的关键部件,它来回移动以确保驱动螺杆的运转。在这种结构中,驱动轴由一组轴向配合的轴承固定。因此,精确的驱动轴对中对于保证泵的使用寿命和轴承至关重要。

Driver Screw

It’s a screw pump’s spinning component. The driver screw connects to the motor’s driving shaft. It aids in the consistent volumetric flow rate of fluid pumping. The timing gear is connected to one end, while the drive shaft is connected to the other.

The driven screw is rotated by the driver screw, which is powered by the motor’s driving shaft. It has a good fit with the driven screw. High-tensile steel is used to make this screw. The driver screw’s main job is to rotate the driven screw through a timing gear, which is an intermediary component.

Driven Screw

High-tensile steel metal is also used for the driven screw. Because of the movement conveyed by the timing gear, it rotates around its axis. It spins in the opposite direction as the driver’s gear. The clearance area of this screw is constant. This aids in catching water inside the restricted space.

The water volume decreases and travels toward the outlet port as the driver and driven screws move together. The fluid’s pressure rises as a result of this movement. It then discharges through the discharge/outlet port.

Timing Gear

The timing gear drives the driven screws in such a way that the female and male rotor assemblies do not make metal-to-metal contact. It establishes a link between the driver and driven screws. The driver screw rotates the timing gear, which then transmits that rotation to the driven screws. It drives screws in this manner. Even if the pump is turned off for a short time, it guarantees that no such connections are made.

Inlet & Outlet Ports

The intake and exit ports of a screw pump are distinct. The water is sucked into the pump through the intake port, and it is discharged through the output port. When the pump ultimately stops, the inlet and output are designed to ensure that there is enough liquid medium. This aids in the delivery of the pump’s initial liquid medium. As a result, the suction tube should not dry out quickly, even if it is empty or dry.

Pressure Relief Valve

Screw pumps are a type of positive displacement pump that builds pressure even while the outlet is closed. This builds up pressure, which can lead to major problems including pump internal part damage and harm to the pump operator. As a result, every positive displacement pump has a relief valve to safeguard the pump, the operator, and any associated gear. Extra pressure is returned to the intake using this valve. Recirculating the exit fluid is another well-known method of reducing extra pressure.

Bearings

During pump operation, the top bearings of a vertically mounted screw pump sustain heavy loads as well as axial and radial stresses. As a result, the load on the lower bearings is minimal.

The bottom bearing’s primary function is to keep the pump’s components aligned. Water screw pumps, roller bearings and slide bearings mounted in parallel, on the other hand, they have relatively low loads. This is due to the fact that the generated radial and axial forces are opposed and cancel one another out.

Driving Shaft

The driving shaft links the pump assembly to the drive motor. This connection is made possible by the use of the proper set of flexible couplings.

This driving shaft is a critical component of many types of pumps, and it goes from side to side to ensure the driver screw’s operation. The driving shaft is secured by a set of bearings that fit in the axial direction in such structures. As a result, accurate driving shaft alignment is critical to preserve the pump’s service life and bearings.

螺杆泵的用途有哪些?

What are the uses of screw pumps?

与离心泵等其他类型的泵相比,螺杆泵通常用于输送粘度较高的流体。使用螺杆泵输送这些流体可以节省能源,且设备体积相对较小。由于螺杆之间没有齿轮啮合,而是依靠流体润滑,因此通常使用具有两个以上螺杆的螺杆泵来输送润滑流体。

When compared to other pump types, such as centrifugal pumps, screw pumps are usually utilized on fluids with a greater viscosity. Moving these fluids using screw pumps results in energy-efficient and relatively small equipment. Because the screws are not geared together and rely on the fluid to lubricate the screws, screw pumps with more than two screws are often utilized for lubricating fluids.

双螺杆泵的螺杆采用齿轮传动,避免相互接触,因此可用于输送非润滑性流体、化学品、食品等。双螺杆泵的流量比多螺杆泵(螺杆数量超过两个)更高。

油基流体、焦油沥青、化学品、工业粘合剂和乳制品是螺杆泵最常见的应用。

The screws of a twin-screw pump are geared to keep them from touching each other, thus they may be used on non-lubricating fluids, chemicals, and foodstuffs, among other things. Twin-screw pumps have a higher flow rate than multi-screw pumps, which have more than two screws.

Oil-based fluids, tar bituminous, chemicals, industrial adhesives, and dairy products are some of the most common applications for a screw pump.

螺杆泵的优缺点

Advantages and Disadvantages of Screw Pumps

以下是螺杆泵的优点和缺点:

螺杆泵的优点

与离心泵相比,螺杆泵具有一些优势。首先,由于泵送的液体沿轴向流动,因此不会产生湍流。这可以防止浓稠液体中形成气泡。

螺杆泵可用于所有流体

• 这些泵易于维护。

• 结构紧凑

• 可能会干涸

• 运行安静

• 这些泵提供稳定、无脉冲的流体流动。

• 该泵具有更高的容积效率。

• 高可靠性

• 维护成本极低

• 高稳健性

• 自吸能力

• 它对灰尘颗粒和水蒸气有很强的抵抗力。

• 螺杆泵不会泵送流体的污染物。

• 您还可以使用螺杆泵泵送高粘度液体,而不会损失流量。

• 它具有无摩擦旋转

• 它以极高的速度泵送流体

• 效率非常高

• 低脉动

螺杆泵的缺点

• 对于小型企业来说,安装需要花费很多钱。

• 为了输送轻质气体,该泵需要气镇。

• 由于没有气镇,对于轻气体来说,它的抽速相对较慢,最终压力较低。

The following are the benefits and drawbacks of a screw pump:

Advantages of Screw Pump

Compared to centrifugal pumps, screw pumps have some benefits. First, there is no turbulence as the pumped liquid flows axially. This prevents bubbles from forming in thick liquids.

Screw Pumps can be used for all fluids

• These pumps have easy maintenance.

• It has a compact construction

• It can run dry

• These have a quiet operation

• These pumps provide a steady, non-pulsing flow of fluid.

• This pump has higher volumetric efficiency.

• High reliability

• It needs very low maintenance

• High robustness

• Self-priming ability

• It is very resistant to dust particles and water vapors.

• The contamination of the fluid is not pumped by a screw pump.

• You can also pump a high viscous liquid with screw pumps without losing the flow.

• It has a frictionless rotation

• It pumps the fluid at a very high speed

• It has very high efficiency

• Low pulsations

Disadvantages of Screw Pump

• Installation costs a lot of money for small businesses.

• To transmit light gas, this pump requires a gas ballast.

• Without a gas ballast, it has a relatively slow pumping speed and a lower final pressure for light gasses.

螺杆泵的应用

Applications of Screw Pumps

• 场地内有多台润滑和液压设备。大型设备需使用螺杆泵供油。

• 螺杆泵更适合泵送较重的油。它们甚至可以泵送粘度更高、流速更快的液体。

• 这些泵能够同时泵送液体和气体。因此,这些泵适用于各种泵送业务。

• 石油和天然气、采矿和工业行业均采用这种泵。

• 陶瓷,油漆,食品,化学品和造纸行业均使用这些泵。

• There are several lubricating and hydraulic machines on the premises. To provide oil to huge equipment, utilize screw pumps.

• Screw pumps are better for pumping heavier oils. They can even pump liquids with higher viscosity and higher flow rates.

• These pumps are capable of pumping both liquid and gas at the same time. As a result, these pumps are used in a variety of pumping businesses.

• The oil and gas, mining, and industrial industries all employ this pump.

• Ceramics, paint, food, chemicals, and paper industries all employ these pumps.

螺杆泵需要启动吗?

Is Priming Necessary for Screw Pumps?

螺杆泵无需启动,因为它们是自吸式泵。泵内产生的真空使泵能够自吸。如果螺杆泵干涸并继续使用,则会损坏泵。

Screw pumps require no priming since they are self-priming. The vacuum created within the pump allows the pump to self-prime. It will damage a screw pump if it becomes dry and continued to be used.

螺杆泵中的正时齿轮是什么?

What Is the Timing Gear In a Screw Pump?

正时齿轮用于驱动从动齿轮,以避免阳转子组件和阴转子组件之间发生金属接触。此外,它还能确保即使泵暂时空转,也不会发生这种接触。

Timing gears are made to drive driven gears in a manner that avoids metal-to-metal contact between male and female rotor assemblies. Also, it ensures that such contact does not occur, even if the pump runs dry temporarily.

关于螺杆泵不同部件的常见问题解答

FAQ Section about Different Parts of Screw Pump

螺杆泵的运行遵循什么原理?

- 正排量原理控制着螺杆泵部件的运行。

Which principle governs the operation of a screw pump?

- The positive displacement principle governs the operation of the parts of the screw pump.

螺杆泵有可能干转吗?

- 是的,螺杆泵的构造使其可以干运转而不会造成任何损坏或启动问题。

Is it possible for a screw pump to run dry?

- Yes, a screw pump is built in such a manner that it may run dry without causing any damage or priming problems.

螺杆泵和齿轮泵有什么区别?

- 齿轮泵和螺杆泵的根本区别在于,螺杆泵比齿轮泵产生的振动、噪音和脉动流量更小。螺杆泵的使用寿命也比齿轮泵更长。

What is the distinction between a screw and a gear pump?

- The fundamental distinction between gear and screw pumps is that a screw pump produces less vibration, noise, and pulsing flow than a gear pump. Screw pumps also outlast gear pumps in terms of service life.

声明:

-文章转载自LINQUIP,由爱泽工业翻译,如有侵权,请联系删除!

-如有偏颇,欢迎指正!

沪公网安备31011002006738号

沪公网安备31011002006738号